Infinity Increases its Sustainability Initiatives

Consumer research indicates that more and more people strongly consider the ecological impact of the products they buy when making purchasing decisions. As environmental awareness increases amongst consumers, product packaging faces increased scrutiny.

Product packaging can disincline ecologically motivated consumers due to an often heavy reliance on plastics and other materials that lack a green reputation.

However, the push for more sustainable packaging is not being led solely by consumers. In the tissue industry, many corporations have recognized the benefits of packaging solutions developed with a focus on the environment.

As the number of consumers and corporations that prioritize sustainability increases, the packaging industry must also prioritize innovative ecological packaging.

Infinity Machine and Engineering Corp. has been on the forefront of innovating sustainable packaging solutions. In 2020, Infinity partnered with Little Rapids Corp. to test and develop ECOVA paper overwrap, a 100% plastic-free, heat-sealable paper wrap, made from 100% recycled fiber. Since then, Infinity has increased its sustainable packaging efforts and prioritized ecological design in its machinery.

One focus for Infinity engineers has been to pioneer more sustainable packaging for individually wrapped tissue rolls. While primarily used as away-from-home tissue in North America and Europe, individually packaged bathroom tissue rolls are very common in the South American consumer sector. Due to the increased amount of packaging material needed to wrap rolls individually, Infinity has designed its single roll wrappers, the S250BRT and the S250HT, to wrap in paper as well as plastic.

However, Infinity’s commitment to sustainable packaging goes beyond primary packaging. Infinity’s C15 Casepacker is capable of loading rolls into corrugated trays. This not only provides stable secondary packaging for tissue products, but it also reduces the amount of material needed for packaging as a tray often uses less than half the cardboard of a standard case. The C15 can also package some tissue roll products directly into corrugated cases without the need for any additional packaging, cutting down on material cost, and material waste.

While prioritizing sustainable packaging is a positive step for the tissue industry, Infinity has taken it a step further by also exploring new ways to reduce the environmental impact of tissue packaging machinery. Infinity machinery can be equipped with IE3 and IE4-rated motors, which use less power while performing at a higher efficiency. Infinity is also trialing monitors on its new Vision G3 multipack wrapper that track the machine’s power usage and air consumption. The information that is collected will be shared with the purchaser which will allow ecological opportunities to be identified and implemented based on the recorded data.

Infinity is also prioritizing sustainability in its research and development department. With about 15% of annual revenue invested in R&D, Infinity has the resources and commitment to developing new machinery and packaging with the planet in mind. Infinity is currently testing ecological materials and new machine designs that will disrupt the current tissue packaging industry and make way for a more sustainable future.

As converters and consumers alike continue to explore a more sustainable future of packaging, Infinity Machine & Engineering Corp. will be with them every step of the way.

Eliminating Machine Maintenance Downtime

With around-the-clock automated operation quickly becoming the global norm in production lines, the negative effects of unscheduled machine downtime become increasingly more pronounced.

High-quality machinery is no longer enough, production lines need reliable customer service and quick turnarounds. This is why Infinity Machine & Engineering’s technical services are designed not just to resolve unplanned maintenance issues but eliminate them entirely.

Infinity prides itself on offering a range of preventative maintenance plans to keep machines and the companies that own them at optimal performance. A fixture of these plans is onsite machine audits performed quarterly, semiannually, or annually. These audits include a thorough inspection of all machines, documented service reports with recommendations after each visit, and additional machine training after the audit’s completion.

However, Infinity’s preventative maintenance begins before the machine leaves the facility. Every machine built by Infinity is put through a rigorous factory acceptance test, testing the customer’s exact specifications, and often running the customer’s actual product. This process ensures the machine is ready for installation and operation as soon as it is delivered. Furthermore, Infinity’s staff boasts a combined 65 years of packaging machinery installation experience, ensuring machine installation time is reduced to a minimum.

Another customer-focused technical service Infinity offers is operator and maintenance technician training. Technician training can be customized based on customer needs, including mechanical training on the customer’s existing Infinity

equipment, and electrical and E&I training. Offerings for Mechanical training include mechanical prints, parts search, rebuilding of assemblies, maintenance inspections, and lubrication routes. Electrical training covers electrical prints, parts search, PLC troubleshooting, replacement parts, and inspections.

To accommodate the round-the-clock production schedule of our customers, Infinity provides 24/7 on-call customer service. Field services techs can be at a customer’s mill within 24-36 hours after a call. Furthermore, Infinity does not charge extra for weekend work from their field service techs, whereas other

companies often charge double time on Sundays.

Another facet of Infinity’s technical services is an extensive spare part inventory. Between their Bologna and Green Bay facilities, Infinity has 20,000 spare parts on hand. There is also a dedicated expedited shipper for emergency situations so

crucial parts can be ordered at a moment’s notice.

Infinity takes consumer convenience in spare part offerings to the next level with predictive maintenance part kits. Through engineering, parts research, and mechanical knowledge of equipment, these kits are designed to maintain full runnability without unplanned downtime. Infinity’s predictive maintenance part kits are customized with common wear parts for all Infinity machine models. These kits also include a parts breakdown list, mechanical prints, and a standard procedure manual to assure the work is done to OEM spec. These give technicians the proper paperwork and parts to ensure the job will be completed properly and in a timely manner.

Infinity was created with a simple vision, to serve the customer, and the technical services offered by Infinity embody that vision. Machine audits that identify issues before they happen, a dedicated 24/7 customer support team, and an extensive spare part inventory all contribute to making this vision reality. When you buy Infinity, you buy peace of mind.

Infinity Euro Expansion

Since 2017, Infinity Machine & Engineering has more than quadrupled the number of machines it has supplied to European tissue plants.

While the American/Italian packaging machinery company has had a large presence in North America for over a decade, as of 2017, its sales in the European market were limited to several machines throughout Italy, Russia, and Slovakia. By the end of 2022, Infinity is scheduled to install over four times the amount of machinery it previously had in Europe, while also expanding sales into six additional European countries: France, Germany, Netherlands, Poland, Spain, and the United Kingdom.

Infinity’s recent rapid growth in the European tissue packaging industry can be attributed to a variety of factors, chiefly among them, the global positioning of the company and the recent increase of Infinity’s manufacturing capabilities.

Infinity is uniquely situated to serve the global market as it has facilities in the two global hubs for tissue paper production, Green Bay, USA, and Bologna, Italy. Infinity’s Italian operation specializes in sales and technical servicing, making Infinity an extremely desirable supplier of machinery for the European tissue industry.

Furthermore, in 2020, Infinity completed the construction of an 8,900 square-meter expansion of its Green Bay facility, allowing for Infinity to offer increased manufacturing capacity to their customers.

Combining Infinity’s global positioning and increased production capacity with the signature build quality and customer service that has made Infinity machinery famous worldwide, it is no surprise that Infinity is one of the fastest-growing suppliers of automated tissue packaging machinery in Europe.

Eurasia Showcase

For the past 19 years, Infinity Machine & Engineering Corp. has disrupted the automated tissue product packaging industry. With machinery in 20 countries across every continent except Antarctica, Infinity has established itself as an industry leader with massive global influence. Committed to serving, not selling, Infinity has built an industry-wide reputation on quality machinery pared with unparalleled service. Now, Infinity invites you to see our machines and services specifically tailored to the European and Asian tissue markets firsthand. From September 12 to October 14, Infinity Italia opens its doors for our first ever Eurasia Showcase!

This exclusive event will feature live runs of Infinity machinery including our newest release, the VISION G3 multipack poly wrapper.

Infinity’s Eurasia showcase will also feature a virtual reality demonstration of our Line Synchronization and Simulation service, which can synchronize production across an entire packaging line ensuring maximum equipment effectiveness.

European and Asian hygienic product manufacturers will not want to miss out on this limited opportunity to witness the latest innovations in automated packaging machinery. To reserve your spot at Infinity’s Eurasia showcase, email the head of our European sales team Daniele Cavallini at dcavallini@infinitymec.com.

We look forward to seeing you there!

18th Anniversary of Infinity's First Casepacker Installation

This summer marked the 18-year anniversary of the installation of the very first Infinity casepacker. The machine remains in operation at Green Bay Converting’s facility in Hobart, WI.

Infinity was originally founded by Scott Santaga, Jeff Cogswell, Tom Wegner, and Doug Wegner as a company that would specialize in the design and manufacturing of poly bundlers. However, Infinity quickly had to adapt to changing circumstances as the first machine order they received was for a casepacker.

Built in a 30ft by 50ft spare room at Scott’s brother’s converting facility, the team would have to dust the machine every morning before continuing the construction process as paper dust from the facility would cover the machine every night.

After months of problem-solving and troubleshooting, Scott, Jeff, Tom, and Doug were able to develop a design that was versatile as well as easy to operate.

Installed on June 4th, 2004, the casepacker is still in operation, with GBC employees referring to it as one of the most reliable machines in their facility.

The first Infinity casepacker was the genesis for what has become an industry leader in automated tissue paper packaging machinery. Expanding beyond casepackers, and the founder’s original vision of poly bundlers, Infinity has increased its product offerings to include poly wrappers, poly baggers, case sealers, conveyor systems, and servo diverters. Infinity machinery has gone on to be installed in 20 countries across every continent except Antarctica.

While a lot has changed since we installed our first case packer, infinity’s unparalleled commitment to quality and customer satisfaction has not. Whether it’s our 24-hour customer service, free CAD layout design, or our signature robust steel frame and guarding, we put serving the customer at the focus of everything we do. If you’re in the market for machinery that will still be running strong 18 years from now, look no further than Infinity.

Ssangyong Purchases A Full Packaging Line From Infinity

Infinity Machine & Engineering Corp. has further increased its footprint in the Asian tissue market as Ssangyong, a leading South Korean brand of hygienic products, purchased a full packaging line from Infinity for their facility in Jochiwon.

Infinity previously sold a full packaging line to South Korean hygienic products brand Monalisa. After the successful installation and operation of this line, Ssangyong was confident in investing in the proven Infinity machinery.

The Ssangyong packaging line features Infinity’s Eclipse T4 multipack poly wrapper, a conveyor with multiple product manipulation devices, and an EPXL poly bundler. All the line’s machinery is built with Infinity’s signature robust steel framing, ensuring that the line will have the durability to last 20+ years.

Infinity’s EPXL poly bundler features a liner servo movement knife and seal jaw, allowing the EPXL to correct misalignments and run registration accurately. The wide frame of the EPXL also allows for wide-format packs, which is essential for the Ssangyong line. Other key features on the EPXL include an integrated diverter and flight bar for simplified product collation, and an automatic poly pull-out cart for safe poly loading.

The Infinity Eclipse T4 multipack wrapper was selected by Ssangyong in large part due to its ability to run a wide range of product configurations. The infeed of the wrapper can run four to five lanes and the wrapper can produce packs five and six rolls deep.

The conveyor system for the Ssangyong line contains multiple product manipulation devices including a Star Wheel capable of unending product at high speeds, an Itapack Handle applicator, and an Infinity Twist-Tipper. Infinity Twist Tippers can tip bundles 90 degrees or be put into a flat position for by-pass via adjustment handwheel. These product manipulation devices will give Ssangyong maximum versatility for bundle pack configurations.

Representatives from Ssangyong offered comprehensive customer input throughout the project and were present for an in-person machine check-out at infinity’s Green Bay, USA facility. Ssangyong’s investment in Infinity machinery ensures they will be able to keep pace with the industry’s growth and adapt to new trends in tissue packaging. The Ssangyong line is set to be installed and in production by the end of July 2022.

Infinity Poly Bagger redesign decreases machine footprint, increases machine production.

While not as conventional as poly bundles, poly bags have unique benefits and applications for tissue product packaging. While bundles are suitable for rolled product, folded product like napkins are too unstable and need to be packaged in poly bags. However, Poly bags are not only for folded products, they are also often used on industrial rolls as the bag end seals are easy to open and are better looking than bundle seals. While poly bags are versatile, the packaging machines that utilize them are not. Most poly baggers on the market today have a long, belted wicket in order to move poly bags to the machine loader. These wickets jut out from the side of the machine and are often 10 feet (3 meters) long. Because of the wicket’s large size and awkward placement, these machines take up a large amount of floor space and can greatly reduce the accessibility of a facility. In addition to this, the traditional belted wicket system has a limited capacity of bags that can be loaded at a time, reducing bagging efficiency.

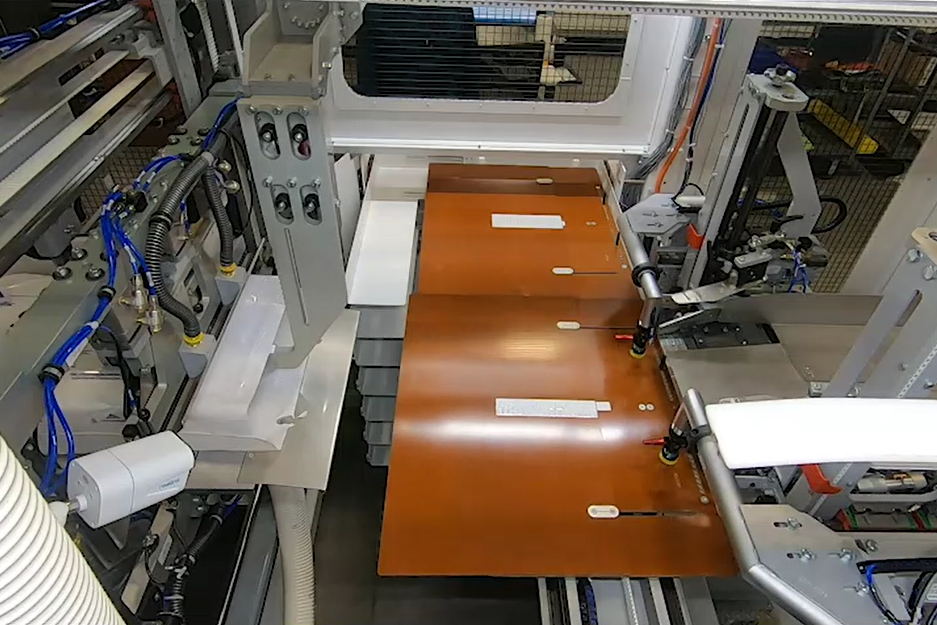

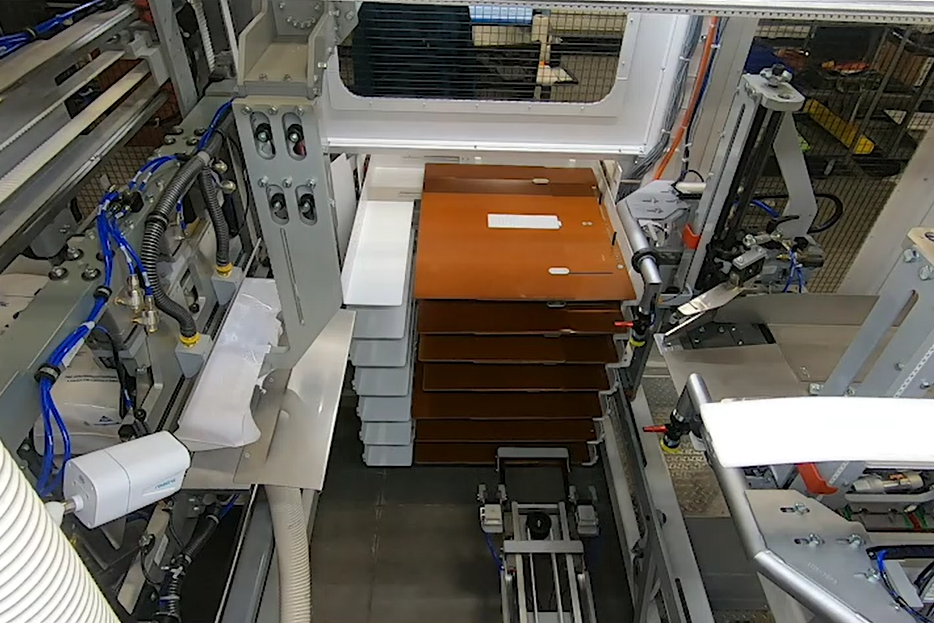

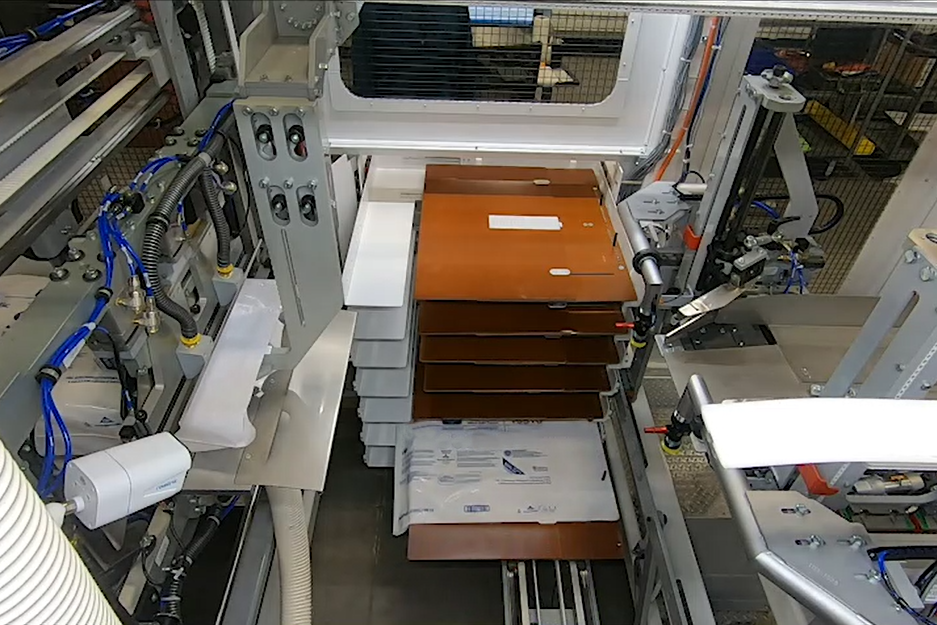

However, Infinity Machine & Engineering Corp. has retooled their poly bagger to eliminate these major drawbacks. Infinity has developed a multi-shelf wicket system for their G10 and G20 poly baggers that eliminates nine feet of wicket length and simultaneously increases poly bag capacity. The new multi-shelf wicket system features seven shelves that can each be filled up to two inches high with poly bags. When one shelf is empty, the machine automatically retracts the shelf and replaces it with a full one. The switch cycle for the Infinity multi-shelf wicket system is also comparable to that of traditional belted wickets, as shelves are swapped and back in production in 15 seconds. Empty retracted shelfs are annunciated by an illuminated signal and can be restocked with bags safely and efficiently while the machine is in operation.

The compact design of the multi-shelf system eliminates a roughly three feet by nine feet section of machine, dramatically decreasing the amount of space needed to accommodate a poly bagger. The trays on Infinity’s new wicket system are also length adjustable, allowing the machine to run shorter poly bags at higher speeds. While Infinity has radically improved the design of their poly bagger, the new multi-shelf wicket system is still compatible with Infinity’s signature Infusion 3 in 1 modular system. The new more efficient poly bagging module can be seamlessly swapped in and out of a common infeed with casepacking and bundling modules, creating the pinnacle of packaging diversity. Infinity’s latest innovation in tissue packaging machinery has finally enabled poly baggers to be as versatile as the packing they support. To learn more about Infinity’s new multi-shelf wicket system, schedule a meeting with the Infinity sales team today!

Spanish tissue paper company, Manipulados Lisma, invests in Infinity Machinery

Growing Spanish tissue manufacturer, Manipulados Lisma, recently purchased three machines from Infinity Italia for its facility in Toledo, Spain.

The purchase breaks new ground for Infinity, as Lisma’s order includes the first VISION G3 multipack wrapper to be installed in the European Union, and the first Infinity Infusion modular system with an i18 bundler and C15 casepacker to be installed in the EU.

Infinity has long been a global leader in automated tissue paper packaging, and Lisma’s investment expands Infinity’s already growing influence in the European market.

Infinity prides itself on manufacturing machinery that is operator-friendly and capable of quick changeovers, two factors that are key to Lisma’s production line. The Infinity machines also have some of the smallest footprints on the market, allowing Lisma to more efficiently utilize space in their facility.

The VISION G3 multipack wrapper is the newest machine release from Infinity, and it features a multitude of new innovations. The machine can produce poly wrapped, paper wrapper, paper tucked, and facial tissue packs, giving Lisma ultimate versatility in production formats. The VISION G3 also features a unique telescoping poly unwind (patent pending), which allows for faster production and better pack quality.

Lisma selected an Infinity i18 Bundler for their line because it is capable of producing large, “European” style bundles for B2B commerce. The i18 will also enable Lisma to run a diverse range of products, as the bundler can run tissue rolls, tissue packs, individual bathroom towels, individual household towels, boxed products, diapers, and industrial rolls.

Infinity’s C15 casepacker has long been a fixture of the tissue products packaging industry, boasting low maintenance and high performance all within a small footprint. Lisma will be able to complete product changeovers on the C15 in as little as 20 minutes, ensuring that they will have maximum overall equipment effectiveness.

While the i18 and C15 are impressive machines in their own right, their compatibility with Infinity’s Infusion Modular system put them in a class above the rest. Developed by Infinity engineers to increase efficiency in a reduced footprint to that of similar linear machines, the 3 in 1 Infusion Modular system incorporates fixed docking stations to create increased packaging flexibility. Bundler, casepacker, and even bagger modules can be attached and detached from a common infeed module, allowing for three different machine combinations in one.

For more than 35 years, Lisma has been a family-owned and operated company, committed to continuous improvement. Lisma has risen to prominence in the European Tissue industry, as it successfully opened in new international markets. Lisma’s purchase of Infinity machinery ensures that they will have the equipment to continue their expansion for many years to come.

WEPA Invests in Infinity Equipment for Multiple Locations

WEPA, a leading tissue product manufacturer in Europe, recently purchased seven machines from Infinity Italia for their facilities in Troyes, France, Swalmen, Netherlands and Piechowice, Poland.

Infinity is supplying two Eclipse T4 Wrappers and two i18 Bundlers for WEPA’s Troyes facility, one Eclipse T4 Wrapper, and one i18 Bundler for WEPA’s facility in Swalmen and in Piechowice, WEPA selected an Infinity C-15 Casepacker for their folded products division.

WEPA was drawn to Infinity’s equipment due to its unique combination of American ruggedness and Italian design refinement. The i18 Bundler is a perfect fit for WEPA’s facilities as it was designed specifically with European markets in mind. The poly bundler features an integrated diverter and flight bar system for easy product collation, as well as an automatic poly reel splice and poly pull-out cart for safe and quick poly loading. In addition to this, an active vacuum comes standard on the i18 Bundler. Excess air is sucked from the bundles’ pre-discharge resulting in a tight, crisp poly wrap.

Another advantage of the i18 Bundler is its compatibility with Infinity’s Infusion modular system. By utilizing the fixed infeed section, the i18 can be coupled with modules, such as an Infinity Casepacker or Bagger. The modules are moved in and out of the docking station which gives WEPA ultimate secondary packaging flexibility without taking up any additional floor space. The “industry original” Infusion modular system was designed by Infinity engineers to overcome the limitations of fixed linear machines while reducing capital investment. As trends in packaging are continuously evolving, Infinity’s innovation allows WEPA to quickly adapt to market changes.

As for primary packaging, WEPA ordered Infinity’s Eclipse T4, which is known as one of the most durable wrappers on the market. Infinity’s commitment to efficiency is on full display in the Eclipse’s overhead system. The Eclipse T4 utilizes a durable AT20 belt and only 24 trolley sections, this decreases the changeover time between different package configurations. Additionally, Infinity’s Eclipse T4 is designed to accept four lanes of infeed and can run an optional fifth. The infeed lanes also have wide diameter capabilities, ensuring the Eclipse will keep pace with new product developments in the Troyes and Swalmen facilities.

Infinity’s reach in Europe was further increased by WEPA’s purchase of the C15 Casepacker for their Piechowice facility. Infinity’s C15 boasts an extremely straightforward design which allows for a 20-minute changeover between case sizes and configurations. Although the machine’s design is simple, its build is robust as the frame and guarding are both constructed using steel. The C15 is also capable of speeds up to 300ppm per index arm, providing maximum efficiency at the infeed of the machine.

A defining feature of the C15 is the machine’s fully positive case erection. Vacuums are utilized on both sides of the case providing a consistent case opening. The positive case erection is perfect for large and small cases, cases with bad score marks as well as cases that are glued together. This design feature will allow WEPA to run at optimal efficiency.

Echoing WEPA’s industry 4.0 efforts, the transaction with Infinity didn’t end with the machine purchase. Emulation engineers from Infinity offices traveled to Swalmen and will be traveling to Troyes to provide Virtual reality training to WEPA employees. This included a fully interactive VR machine changeover, which allowed WEPA employees to become familiar with their machines weeks before they arrived at their facilities.

Infinity also equipped the machines with a data collecting and remotely accessible eWON device. This enables WEPA to track production times, faults, and speed. This information will be accessible remotely through email notifications or web browsers. The Troyes facility will also have light annunciation on their i18 Bundlers to provide changeover assistance. The light annunciation illuminates change-over points on the adjustment scales.

WEPA’s recent investment reflects Infinity’s growing reach in the European market and is further proof Infinity is the global leader in automated tissue paper packaging machinery.

Now Back On the World Stage

Infinity Machine and Engineering Corporation, a global leader in automated tissue packaging equipment is excited to be presenting itself on the global stage once again.

Infinity Machine and Engineering Corporation, a global leader in automated tissue packaging equipment is excited to be presenting itself on the global stage once again.

Due to the Coronavirus pandemic, many tradeshows and industry events were put on hiatus. However, as the world transitions to its next stage of pandemic management, many industry events are back on schedule.

Infinity will feature in Tissue World Miami on March 16-18, Tissue and Paper Bangkok on September 14-16, and finish their global tour in Lucca Italy at MIAC on October 12-14. Infinity will be featured at booth B30 at Tissue World Miami, booth D10 at Tissue and Paper Bangkok and booth 27M at MIAC.

While the world seemed to be on pause the last couple of months, Infinity engineers were hard at work developing the latest innovations in automated sanitary paper product packaging. The pinnacle of these pursuits, and the key focus of Infinity’s 2022 world tour is their new VISION G3 Multipack Wrapper.

Capable of producing packs five lanes wide, three layers high and six rows deep, the VISION G3 redefines versatility for multipack wrappers. The VISION G3 can also produce poly wrapped packs, paper wrapped packs, paper tucked packs and facial tissue packs.

Infinity engineers didn’t sacrifice speed for this increased versatility either. Because of a revolutionary telescoping design (patent pending) on the poly unwind, the VISION G3 is capable of faster speeds and improved pack quality.

Tissue World Miami, Tissue and Paper Bangkok, and MIAC are the perfect opportunities to learn more about the VISION G3 firsthand from Infinity’s experienced sales staff. However, if you are unable to make it to these industry events, the VISION G3 will be available for viewing at Infinity’s facilities in Green Bay Wisconsin and Bologna Italy during their open house showcase, and anytime online at infinitymec.com/vision-g3-wrapper.