Infinity Poly Bagger redesign decreases machine footprint, increases machine production.

While not as conventional as poly bundles, poly bags have unique benefits and applications for tissue product packaging. While bundles are suitable for rolled product, folded product like napkins are too unstable and need to be packaged in poly bags. However, Poly bags are not only for folded products, they are also often used on industrial rolls as the bag end seals are easy to open and are better looking than bundle seals. While poly bags are versatile, the packaging machines that utilize them are not. Most poly baggers on the market today have a long, belted wicket in order to move poly bags to the machine loader. These wickets jut out from the side of the machine and are often 10 feet (3 meters) long. Because of the wicket’s large size and awkward placement, these machines take up a large amount of floor space and can greatly reduce the accessibility of a facility. In addition to this, the traditional belted wicket system has a limited capacity of bags that can be loaded at a time, reducing bagging efficiency.

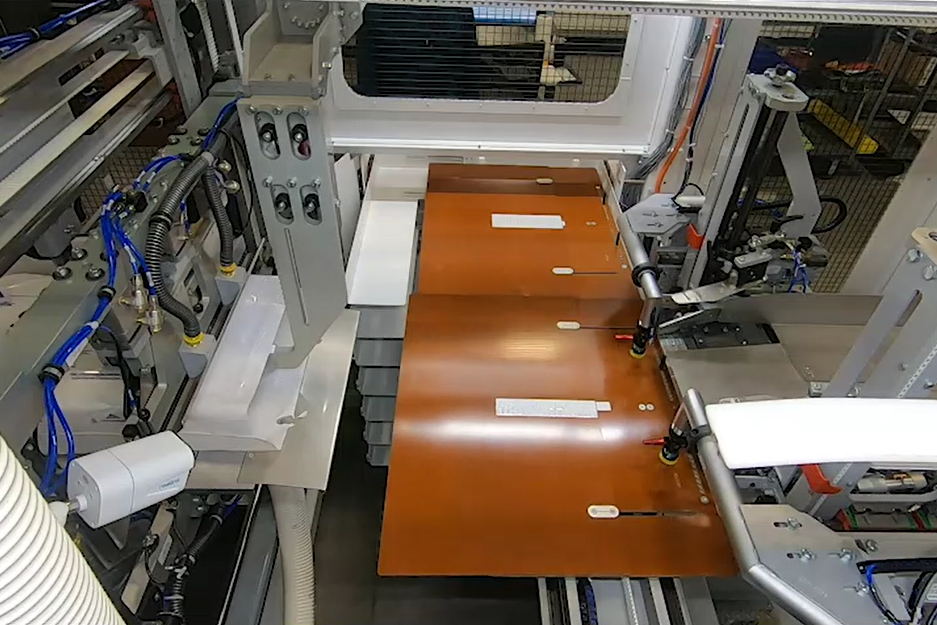

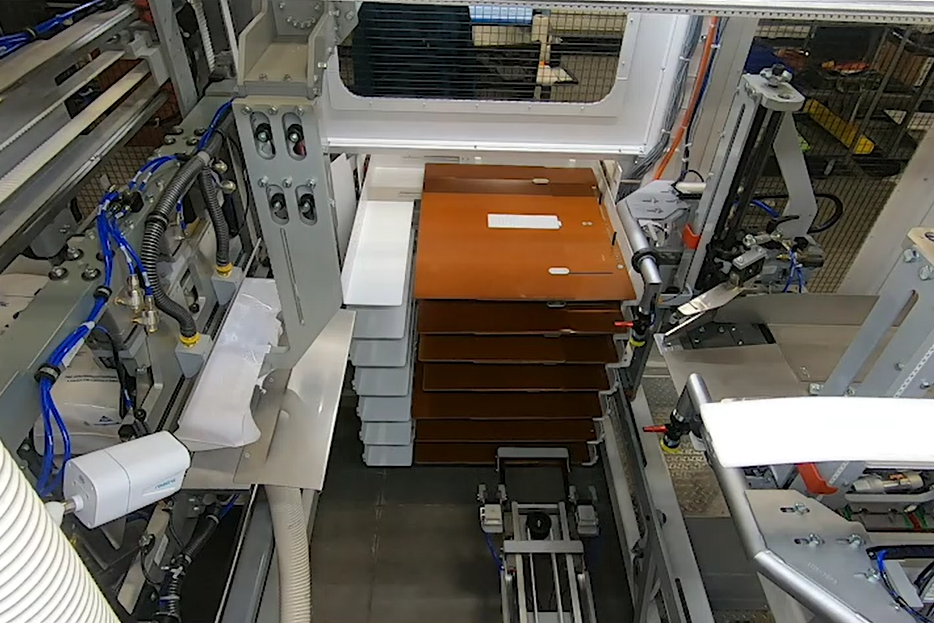

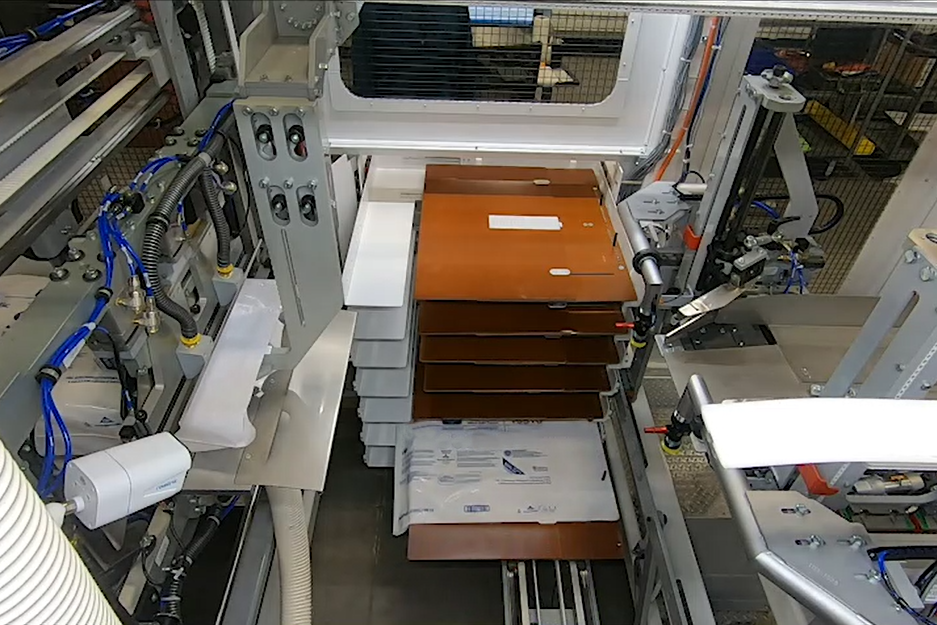

However, Infinity Machine & Engineering Corp. has retooled their poly bagger to eliminate these major drawbacks. Infinity has developed a multi-shelf wicket system for their G10 and G20 poly baggers that eliminates nine feet of wicket length and simultaneously increases poly bag capacity. The new multi-shelf wicket system features seven shelves that can each be filled up to two inches high with poly bags. When one shelf is empty, the machine automatically retracts the shelf and replaces it with a full one. The switch cycle for the Infinity multi-shelf wicket system is also comparable to that of traditional belted wickets, as shelves are swapped and back in production in 15 seconds. Empty retracted shelfs are annunciated by an illuminated signal and can be restocked with bags safely and efficiently while the machine is in operation.

The compact design of the multi-shelf system eliminates a roughly three feet by nine feet section of machine, dramatically decreasing the amount of space needed to accommodate a poly bagger. The trays on Infinity’s new wicket system are also length adjustable, allowing the machine to run shorter poly bags at higher speeds. While Infinity has radically improved the design of their poly bagger, the new multi-shelf wicket system is still compatible with Infinity’s signature Infusion 3 in 1 modular system. The new more efficient poly bagging module can be seamlessly swapped in and out of a common infeed with casepacking and bundling modules, creating the pinnacle of packaging diversity. Infinity’s latest innovation in tissue packaging machinery has finally enabled poly baggers to be as versatile as the packing they support. To learn more about Infinity’s new multi-shelf wicket system, schedule a meeting with the Infinity sales team today!

Spanish tissue paper company, Manipulados Lisma, invests in Infinity Machinery

Growing Spanish tissue manufacturer, Manipulados Lisma, recently purchased three machines from Infinity Italia for its facility in Toledo, Spain.

The purchase breaks new ground for Infinity, as Lisma’s order includes the first VISION G3 multipack wrapper to be installed in the European Union, and the first Infinity Infusion modular system with an i18 bundler and C15 casepacker to be installed in the EU.

Infinity has long been a global leader in automated tissue paper packaging, and Lisma’s investment expands Infinity’s already growing influence in the European market.

Infinity prides itself on manufacturing machinery that is operator-friendly and capable of quick changeovers, two factors that are key to Lisma’s production line. The Infinity machines also have some of the smallest footprints on the market, allowing Lisma to more efficiently utilize space in their facility.

The VISION G3 multipack wrapper is the newest machine release from Infinity, and it features a multitude of new innovations. The machine can produce poly wrapped, paper wrapper, paper tucked, and facial tissue packs, giving Lisma ultimate versatility in production formats. The VISION G3 also features a unique telescoping poly unwind (patent pending), which allows for faster production and better pack quality.

Lisma selected an Infinity i18 Bundler for their line because it is capable of producing large, “European” style bundles for B2B commerce. The i18 will also enable Lisma to run a diverse range of products, as the bundler can run tissue rolls, tissue packs, individual bathroom towels, individual household towels, boxed products, diapers, and industrial rolls.

Infinity’s C15 casepacker has long been a fixture of the tissue products packaging industry, boasting low maintenance and high performance all within a small footprint. Lisma will be able to complete product changeovers on the C15 in as little as 20 minutes, ensuring that they will have maximum overall equipment effectiveness.

While the i18 and C15 are impressive machines in their own right, their compatibility with Infinity’s Infusion Modular system put them in a class above the rest. Developed by Infinity engineers to increase efficiency in a reduced footprint to that of similar linear machines, the 3 in 1 Infusion Modular system incorporates fixed docking stations to create increased packaging flexibility. Bundler, casepacker, and even bagger modules can be attached and detached from a common infeed module, allowing for three different machine combinations in one.

For more than 35 years, Lisma has been a family-owned and operated company, committed to continuous improvement. Lisma has risen to prominence in the European Tissue industry, as it successfully opened in new international markets. Lisma’s purchase of Infinity machinery ensures that they will have the equipment to continue their expansion for many years to come.