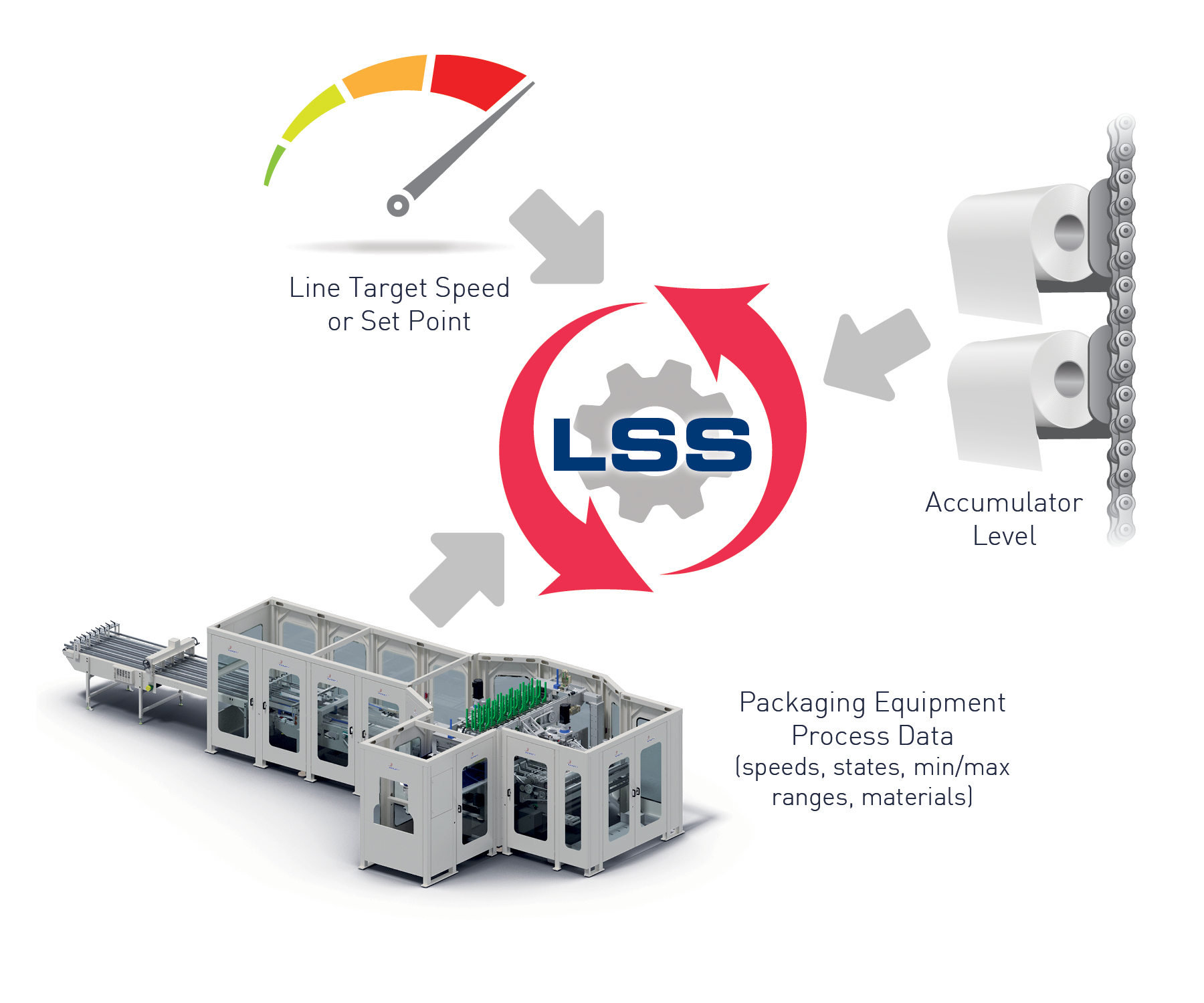

What is LSS?

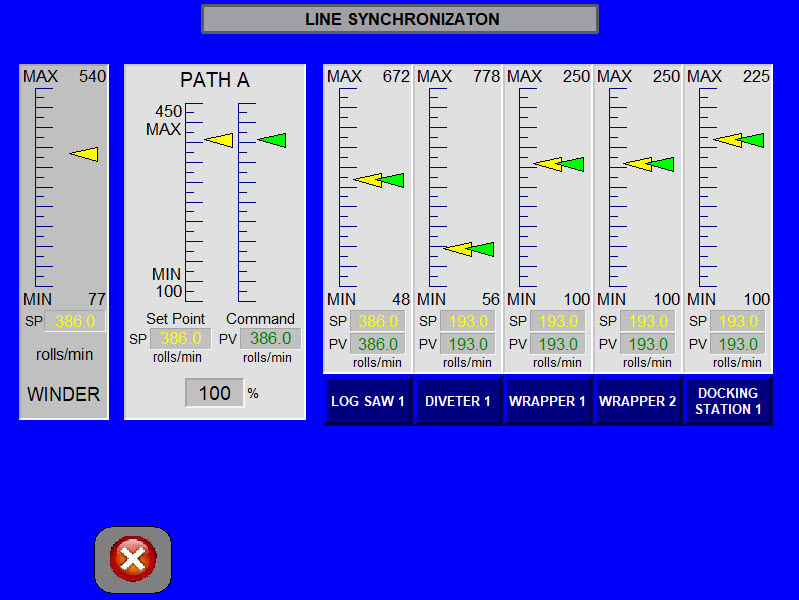

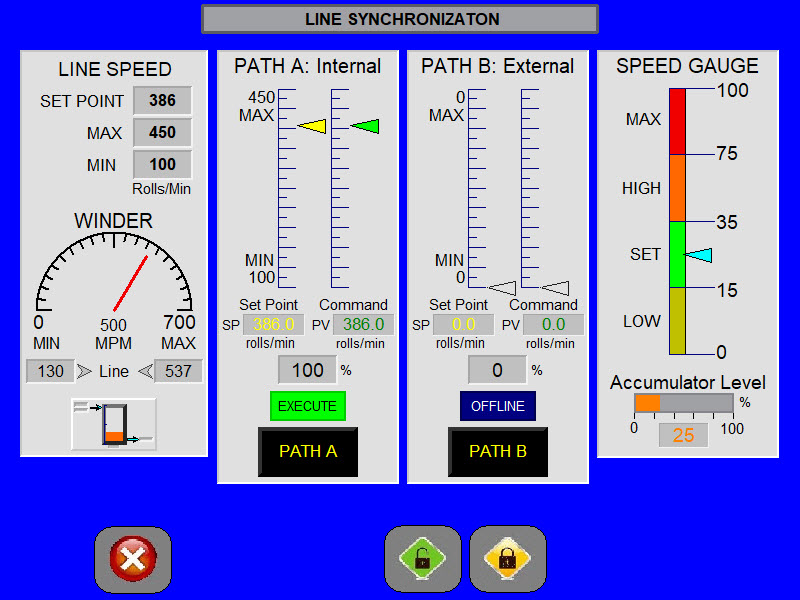

Infinity “Line Synchronization and Simulation”, or “LSS”, gives the ability to control the speed of the line and harmonize the downstream system as a single unit, not separate individual pieces. By programming the line such that each machine is just part of the overall process and being able automatically predict and/or react to the line, we can ensure maximum uptime and fewer line interruptions.

Why LSS?

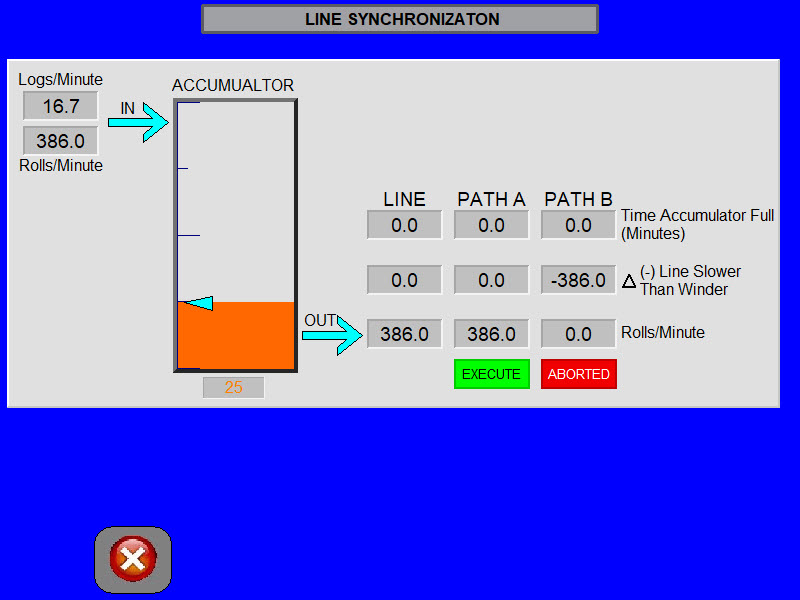

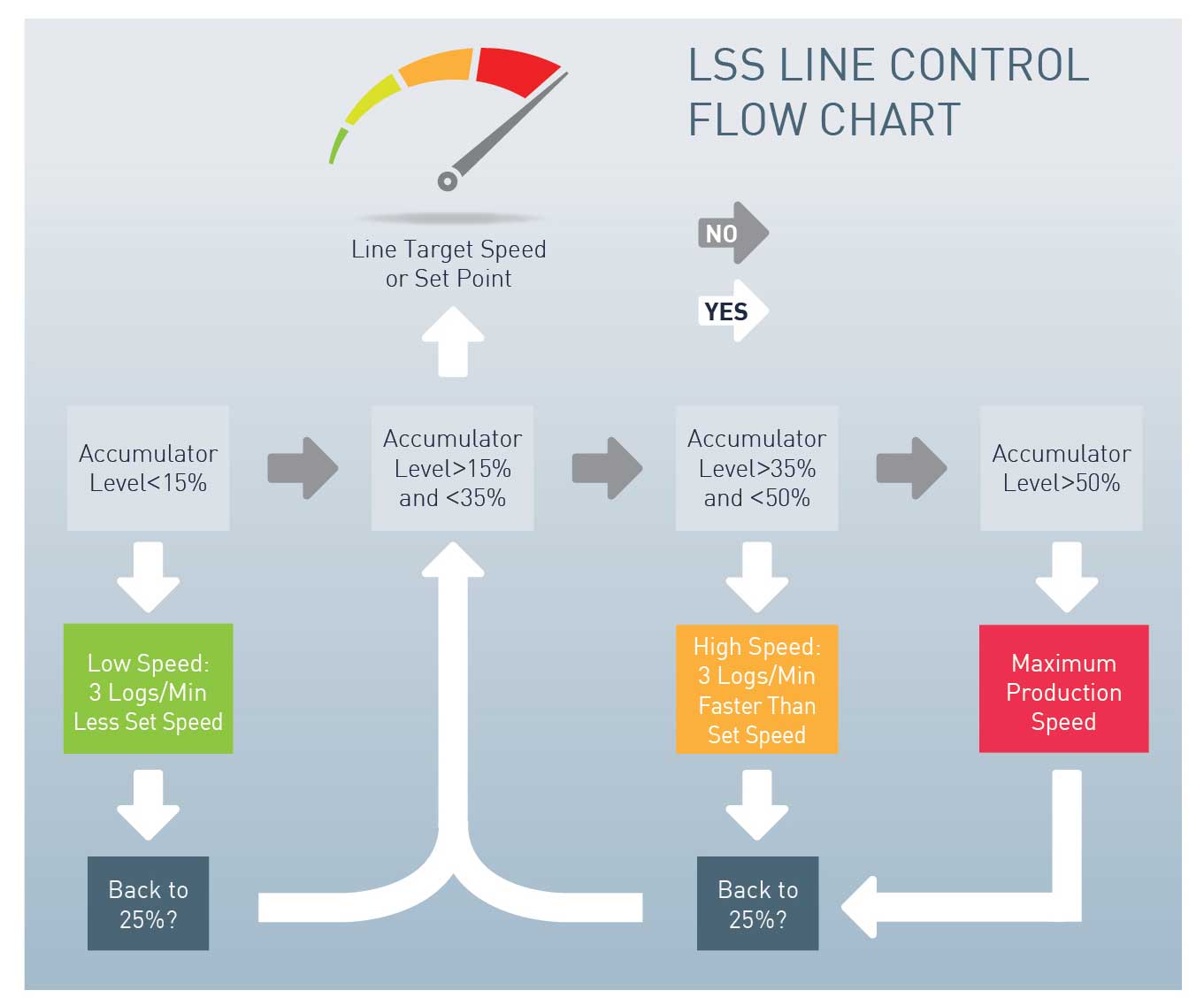

For a typical application, the purpose of LSS is to keep the converting line running by maximizing overall line flow and by maintaining the proper accumulator levels. The converting line needs to have the ability to feed enough product for wrappers to continuously run, while the downstream equipment needs to be able to run faster than target speed when there is a backlog. By defining line bottlenecks and directing the line to only run at the speed required by this bottleneck, the LSS ensures that machines are running at their maximum uptime and least mechanical stress. During line upsets (jams, material changes, etc.), how the machines react to one another and how quickly they resume full production makes a big difference in overall line OEE. The LSS ensures that this is maximized.

Key LSS Benefits

LSS has many different features that can be completely customizable based on customer needs. Some of the basic features include:

- Synchronizing the machine speeds to balance the line

- Reducing the amount of speed changes

- Monitoring machine availability/capability

- Monitoring of accumulator level in relation to packaging line changes

- Maximize overall performance and flexibility of the line

- Ability to adjust line for imminent material changes, switching output from one path to another

- In a two-leg packaging system, prioritizing one leg over another

- Changing speed or accumulator function based on production line interruptions

- Change log distribution based on percentage