Infinity expands palletizer offerings with new Cobot palletizer

Infinity Machine and Engineering Corp. is proud to announce the newest addition to our line of palletizing solutions, the Infinity cobot.

Infinity’s cobot palletizer is engineered to increase productivity while seamlessly integrating with an existing workforce and facility.

Designed to stack finished product onto pallets for shipping or storage, the palletizer can complete its operations safely alongside a human workforce without the need for guarding or additional safety devices.

The advanced safety system of Infinity’s cobot can identify if someone or something is within the radius of its arm. If a person or object enters the cobot’s range of motion, the palletizer automatically reduces its speed to a crawl. If the arm of the cobot makes contact with the object, it immediately freezes in position.

Combine this sophisticated safety system with the cobot’s two standard build stations and operators are able to remove completed pallet stacks from the inactive build station while the machine is still in motion, allowing for optimal efficiency in the pallet building process.

Operator convenience is also prioritized in the palletizer’s design as key operating factors like recipe, product location, and product type can be modified directly from a touchscreen tablet.

The Infinity Cobot is set to redefine the efficiency of your operations with an advanced safety system allowing for uninterrupted production runs and improved operator convenience.

Since debuting our line of palletizing solutions in 2023, we have continuously looked for

ways to cater to the needs of our customers.

Infinity Machine & Engineering Corp. to exhibit at Tissue World 2025

From April 8 th to April 10 th , Infinity Machine & Engineering Corp. will return to the Messe Dusseldorf to exhibit at Tissue World 2025.

The previous edition of Tissue World took place last January in Miami and brought together professionals from across the American tissue industry. This year’s exhibition is expected to draw visitors from across Europe and will focus on future proofing the tissue industry for sustainable growth.

Since establishing a base for its European operations in Bologna, Infinity has developed a significant presence in Europe. In the last ten years, Infinity has sold over 120 units of machinery to customers across 15 European countries.

A key piece of Infinity’s machine catalog that has greatly contributed to its growth in Europe is the Optic M1 poly bundler. Designed with the unique needs of the European tissue market in mind, the Optic M1 boasts swappable flight bar and upender units. The interchangeable upender/flight bar units give the machine increased flexibility on the product infeed, allowing for the production of bundles with vertical and horizontal roll formats.

To learn more about the Optic M1, as well as Infinity’s entire roster of innovative tissue packaging machinery, be sure to visit Infinity’s booth at space F40.

South Korean Tissue Manufacturer Increases Investment in Infinity Machinery

MSS Holdings of South Korea has purchased its third packaging line from international leader in automated tissue packaging machinery, Infinity Machine and Engineering Corp.

This most recent investment in Infinity equipment by MSS Holdings is the company’s second Infinity packaging line purchased for their brand Monalisa.

Infinity will be providing an EPXL poly bundler, VISION G3 multipack wrapper, and conveyor system for the project.

The EPXL poly bundler features a wide frame that allows the machine to create wide format packs, which are common in the South Korean market. Additionally, the EPXL also boasts an integrated diverter and flight bar for simplified product collation, and an automatic poly pull out cart for safe and convenient poly loading.

MSS Holdings selected the VISION G3 multipack wrapper for their new packaging line as Infinity’s most advanced wrapper. The VISION G3 Infinity will be supplying to MSS Holdings will feature an external handle applicator, giving MSS holdings the ability to differentiate their product with increased consumer convenience.

Infinity has steadily increased its influence in the Asian tissue market as Infinity packaging machinery is operated across South Korea, Thailand, Indonesia, and the Philippines.

Infinity Machine & Engineering Corp. to exhibit at Tissue World 2024

From January 31st to February 2nd, Infinity Machine & Engineering Corp. will return to the Miami Beach Convention Center to exhibit at Tissue World 2024.

The previous show, Tissue World 2023, took place in Dusseldorf and brought together tissue industry professionals across Europe. This year’s exhibition promises to draw representatives across the North American, Latin American, and South American tissue markets.

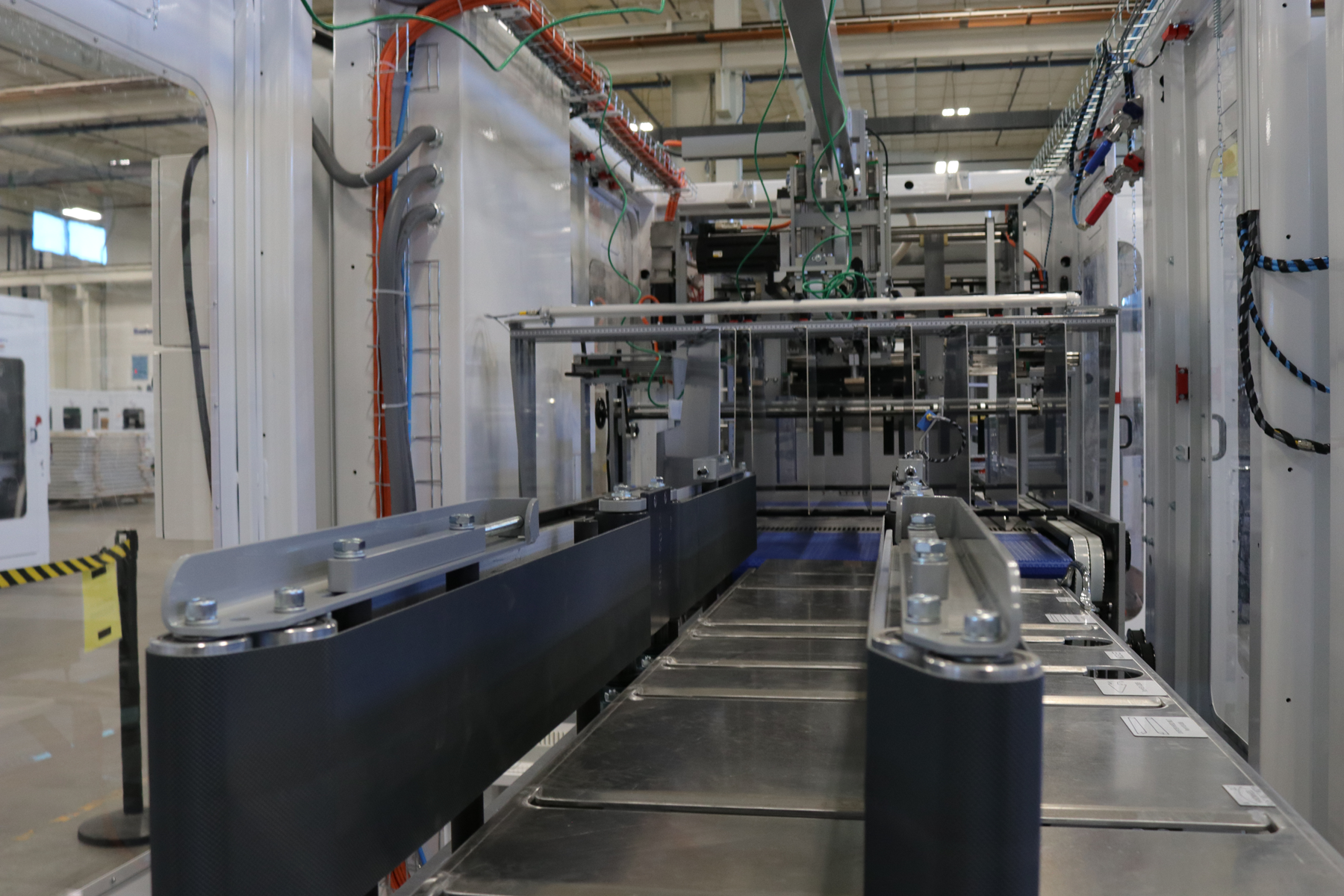

At this year’s exhibition, Infinity will officially launch their line of palletizing solutions, expanding the Infinity product line beyond primary and secondary tissue packaging.

Responding to consumer demand, Infinity palletizing solutions can be integrated with Infinity packaging lines, enabling Infinity machinery to automate every step of the tissue production process after the log saw.

A key aspect of Infinity’s palletizing solutions is their modularity. The unit is made up of modular palletizer sections that can be arranged into countless different layouts in order to accommodate production requirements, as well as facility limitations. The flexibility created by these palletizer sections make it perfect for a multitude of product lines, from single product, to large-scale, multi-line operations.

The palletizer segments offered by Infinity include automatic slip sheet placement, integrated labeling, and fully automatic, fully servo stretch wrapping. All designed to provide extreme efficiency and versatility in a minimal amount of space.

To learn more about the palletizing solutions offered by Infinity, as well as new developments among its existing roster of machinery, stop by the Infinity booth located at space B30.

Infinity Machine 20th Anniversary

In 2004, Scott Santaga, Jeffery Cogswell Thomas Wegner and Douglas Wegner founded Infinity Machine & Engineering Corp. with a simple guiding principle, to serve the customer. While a lot about Infinity has changed since 2004, the commitment to serve the customer never has.

Since the beginning, Infinity has been defined by the entrepreneurial spirit of its founders. What began as a company that operated out of a 9X15 square meter facility has grown to be the premier name in automated tissue packaging.

Originally, Infinity was founded as a company that would design and build poly bundlers, however plans changed when Infinity’s first order was for a casepacker. Infinity’s founders adapted to the needs of the customer and designed a casepacker that was flexible and operator friendly. The first Infinity casepacker is still in operation today, a testament to its design and build quality.

Throughout its 20-year history, Infinity has continuously pushed the boundaries of what tissue packaging machinery can be capable of. Debuting in 2005, Infinity’s signature Infusion modular system utilizes interchangeable packaging modules and a fixed, common infeed unit. This revolutionary design allows for casepacking, bundling and bagging to occur all in one place, providing unmatched flexibility for converting lines. The Infusion modular system has become a global success with systems installed across North America, Europe, and Asia.

In 2010 Infinity added the talents of Italian technical specialist and sales staff with the creation of Infinity Italia. With the addition, American and Italian engineers combined their expertise to develop Infinity’s first poly wrappers. Among these wrappers was the Solo 250, a single roll wrapper capable of running production speeds of 250 rolls a minute. Since expanding the product line, nearly 200 poly wrappers have been installed, making them an iconic part of Infinity’s product mix.

Infinity has not been limited to innovations in machinery, the company also responded to their customer’s desire for more environmentally conscious packaging solutions. In 2020 Infinity partnered with Little Rapids Corp. to develop and test Ecova, a 100% plastic-free paper overwrap made from recycled materials. Since the debut of Ecova, Infinity has continued to prioritize sustainability with continual investment in ecologically focused research and development.

With machinery installed in over 20 countries, across every continent except Antarctica, infinity has established itself as the international industry leader in automated tissue packaging machinery. From France to South Korea, Infinity customers know that Infinity provides quality machinery and unparalleled customer service.

To accommodate the company’s rapid growth, Infinity’s headquarters has been expanded twice since it opened in 2008. The most recent expansion, which took place in 2020, increased the size of the facility to 16,000 square meters. Infinity has also increased its staff to over 200 employees between its Italian and American operations, nearly doubling in size from the total five years ago. However, the success of Infinity cannot solely be measured in facility expansions, or employee growth, it is also measured in the pride Infinity employees have in building the best tissue packaging machinery on the planet.

Infinity has undergone a multitude of changes throughout its 20-year history. However, through multiple expansions to its roster of machinery, continuous increases in international sales, and breakthroughs in ecological packaging, one thing has remained constant, Infinity’s commitment to serve its customers.

Serbian Tissue Manufacturer Invest in Infinity Machinery

Drenik ND d.o.o. a Serbian manufacturer of hygienic paper products and one of the largest cellulose manufacturers in Southeast Europe, has purchased six machines from Infinity Machine & Engineering Corp. The sale was completed in collaboration with Impex Continental.

To keep up with their increased production demands and maintain their strict quality standards, Drenik selected Infinity’s most recent machine releases, the VISION G3 multipack wrapper and the Optic M1 poly bundler. The two VISION G3s and four Optic M1s will be installed at Drenik’s facility in Belgrade, Serbia. These machines will continue the trend of Infinity’s recent rapid growth in Europe. In the last six years, Infinity has more than quadrupled its machine presence in Europe, supplying nine European countries with automated tissue packaging machinery.

Infinity’s VISION G3 multipack wrapper boasts an array of new innovative features. A patent pending telescoping poly unwind enables faster production speeds while improving pack quality. The Vision G3 can also produce poly wrapped, paper wrapped, paper tucked and facial tissue packs, providing Drenik with unparallel packaging versatility.

The Optic M1 poly bundler is a perfect fit for Drenik’s line as it is designed to produce large format bundles, common in the European market. The unique interchangeable upender and flight bar units on the Optic also appealed to Drenik as they allow for the creation of both “core up” and “core down” pack configurations.

When looking for the right partner for their largest investment of the year, Drenik was drawn to Infinity in large part due to their shared enthusiasm for success and innovation. Founded in 1995, Drenik started as a company that solely manufactured diapers and sanitary pads, however, the company soon expanded into bathroom tissue and household towel rolls. Today, Drenik produces over 100,000 tons of tissue a year and employs over 800 people between its facilities in Serbia and Hungary.

Throughout Drenik’s growth, they have been a company driven by sustainable practices, this drive goes hand in hand with Infinity’s expansive sustainability initiatives. The Optic M1 and VISION G3 can be equipped with IE3 and IE4 rated motors, which operate at a higher efficiency while using less power. The VISION G3 can also wrap rolls in paper, reducing plastic consumption and promoting more ecological packaging.

Drenik’s investment in Infinity machinery ensures that they will have the flexibility to meet any possible market need, while promoting sustainable practices.

Infinity Servo Diverters Enable Ultimate Line Optimization

As the tissue-converting industry continues to experience increased growth, flexibility is no longer a goal of converting lines, it is a necessity.

Converters need to offer lines with optimized speed and diverse products to keep up with consumer preferences and demand. Infinity’s line of servo diverters meets and surpasses this need for flexibility.

All four models of Infinity servo diverter can act as the central brain of a converting line, efficiently balancing incoming product to the required downstream machinery while ensuring a steady, even flow of product.

Infinity diverters also help reduce the need for excess conveyors and additional floor space by utilizing precise, variable control. The diverter’s ability to merge, distribute and control makes them the smartest, most flexible diverters on the market.

Each of Infinity’s diverters can accommodate unique needs for different converting lines. The Telescopic Servo Merge diverter, or TSM, is specifically designed to balance converting lines from four lanes to three or two lanes.

The Quick Switch diverter is similar to the infeed indexers that appear on most of Infinity’s casepackers and bundlers. It is offered as a one, two, or three-arm diverter that usually takes packs or roll products and distributes them to the necessary lanes.

Infinity designed its Single Roll Laner diverter to be the perfect fit for lines with a multipack wrapper and single roll wrappers. The SRL diverter sets the industry standard for diverters that distribute four lanes to five, six, or even seven lanes.

Featuring a unique servo-controlled pivoting system, Infinity’s C2L diverter is a great fit for lines with dual packaging legs and one log saw. The C2L diverter can take four lanes and distribute to two layers of four-lane conveyor.

Some additional key features that make Infinity diverters the best on the market are a discharge lane selection on the HMI as well as a toolless changeover.

With four unique models of diverter, Infinity Machine & Engineering can provide the perfect solution to make your line faster, smarter, and more flexible.

Infinity Increases its Sustainability Initiatives

Consumer research indicates that more and more people strongly consider the ecological impact of the products they buy when making purchasing decisions. As environmental awareness increases amongst consumers, product packaging faces increased scrutiny.

Product packaging can disincline ecologically motivated consumers due to an often heavy reliance on plastics and other materials that lack a green reputation.

However, the push for more sustainable packaging is not being led solely by consumers. In the tissue industry, many corporations have recognized the benefits of packaging solutions developed with a focus on the environment.

As the number of consumers and corporations that prioritize sustainability increases, the packaging industry must also prioritize innovative ecological packaging.

Infinity Machine and Engineering Corp. has been on the forefront of innovating sustainable packaging solutions. In 2020, Infinity partnered with Little Rapids Corp. to test and develop ECOVA paper overwrap, a 100% plastic-free, heat-sealable paper wrap, made from 100% recycled fiber. Since then, Infinity has increased its sustainable packaging efforts and prioritized ecological design in its machinery.

One focus for Infinity engineers has been to pioneer more sustainable packaging for individually wrapped tissue rolls. While primarily used as away-from-home tissue in North America and Europe, individually packaged bathroom tissue rolls are very common in the South American consumer sector. Due to the increased amount of packaging material needed to wrap rolls individually, Infinity has designed its single roll wrappers, the S250BRT and the S250HT, to wrap in paper as well as plastic.

However, Infinity’s commitment to sustainable packaging goes beyond primary packaging. Infinity’s C15 Casepacker is capable of loading rolls into corrugated trays. This not only provides stable secondary packaging for tissue products, but it also reduces the amount of material needed for packaging as a tray often uses less than half the cardboard of a standard case. The C15 can also package some tissue roll products directly into corrugated cases without the need for any additional packaging, cutting down on material cost, and material waste.

While prioritizing sustainable packaging is a positive step for the tissue industry, Infinity has taken it a step further by also exploring new ways to reduce the environmental impact of tissue packaging machinery. Infinity machinery can be equipped with IE3 and IE4-rated motors, which use less power while performing at a higher efficiency. Infinity is also trialing monitors on its new Vision G3 multipack wrapper that track the machine’s power usage and air consumption. The information that is collected will be shared with the purchaser which will allow ecological opportunities to be identified and implemented based on the recorded data.

Infinity is also prioritizing sustainability in its research and development department. With about 15% of annual revenue invested in R&D, Infinity has the resources and commitment to developing new machinery and packaging with the planet in mind. Infinity is currently testing ecological materials and new machine designs that will disrupt the current tissue packaging industry and make way for a more sustainable future.

As converters and consumers alike continue to explore a more sustainable future of packaging, Infinity Machine & Engineering Corp. will be with them every step of the way.

Infinity Euro Expansion

Since 2017, Infinity Machine & Engineering has more than quadrupled the number of machines it has supplied to European tissue plants.

While the American/Italian packaging machinery company has had a large presence in North America for over a decade, as of 2017, its sales in the European market were limited to several machines throughout Italy, Russia, and Slovakia. By the end of 2022, Infinity is scheduled to install over four times the amount of machinery it previously had in Europe, while also expanding sales into six additional European countries: France, Germany, Netherlands, Poland, Spain, and the United Kingdom.

Infinity’s recent rapid growth in the European tissue packaging industry can be attributed to a variety of factors, chiefly among them, the global positioning of the company and the recent increase of Infinity’s manufacturing capabilities.

Infinity is uniquely situated to serve the global market as it has facilities in the two global hubs for tissue paper production, Green Bay, USA, and Bologna, Italy. Infinity’s Italian operation specializes in sales and technical servicing, making Infinity an extremely desirable supplier of machinery for the European tissue industry.

Furthermore, in 2020, Infinity completed the construction of an 8,900 square-meter expansion of its Green Bay facility, allowing for Infinity to offer increased manufacturing capacity to their customers.

Combining Infinity’s global positioning and increased production capacity with the signature build quality and customer service that has made Infinity machinery famous worldwide, it is no surprise that Infinity is one of the fastest-growing suppliers of automated tissue packaging machinery in Europe.

Eurasia Showcase

For the past 19 years, Infinity Machine & Engineering Corp. has disrupted the automated tissue product packaging industry. With machinery in 20 countries across every continent except Antarctica, Infinity has established itself as an industry leader with massive global influence. Committed to serving, not selling, Infinity has built an industry-wide reputation on quality machinery pared with unparalleled service. Now, Infinity invites you to see our machines and services specifically tailored to the European and Asian tissue markets firsthand. From September 12 to October 14, Infinity Italia opens its doors for our first ever Eurasia Showcase!

This exclusive event will feature live runs of Infinity machinery including our newest release, the VISION G3 multipack poly wrapper.

Infinity’s Eurasia showcase will also feature a virtual reality demonstration of our Line Synchronization and Simulation service, which can synchronize production across an entire packaging line ensuring maximum equipment effectiveness.

European and Asian hygienic product manufacturers will not want to miss out on this limited opportunity to witness the latest innovations in automated packaging machinery. To reserve your spot at Infinity’s Eurasia showcase, email the head of our European sales team Daniele Cavallini at dcavallini@infinitymec.com.

We look forward to seeing you there!