Jetzt zurück auf der Weltbühne

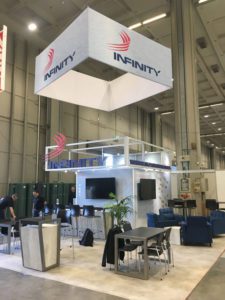

Infinity Machine and Engineering Corporation, a global leader in automated tissue packaging equipment is excited to be presenting itself on the global stage once again.

Infinity Machine and Engineering Corporation, a global leader in automated tissue packaging equipment is excited to be presenting itself on the global stage once again.

Due to the Coronavirus pandemic, many tradeshows and industry events were put on hiatus. However, as the world transitions to its next stage of pandemic management, many industry events are back on schedule.

Infinity will feature in Tissue World Miami on March 16-18, Tissue and Paper Bangkok on September 14-16, and finish their global tour in Lucca Italy at MIAC on October 12-14. Infinity will be featured at booth B30 at Tissue World Miami, booth D10 at Tissue and Paper Bangkok and booth 27M at MIAC.

While the world seemed to be on pause the last couple of months, Infinity engineers were hard at work developing the latest innovations in automated sanitary paper product packaging. The pinnacle of these pursuits, and the key focus of Infinity’s 2022 world tour is their new VISION G3 Multipack Wrapper.

Capable of producing packs five lanes wide, three layers high and six rows deep, the VISION G3 redefines versatility for multipack wrappers. The VISION G3 can also produce poly wrapped packs, paper wrapped packs, paper tucked packs and facial tissue packs.

Infinity engineers didn’t sacrifice speed for this increased versatility either. Because of a revolutionary telescoping design (patent pending) on the poly unwind, the VISION G3 is capable of faster speeds and improved pack quality.

Tissue World Miami, Tissue and Paper Bangkok, and MIAC are the perfect opportunities to learn more about the VISION G3 firsthand from Infinity’s experienced sales staff. However, if you are unable to make it to these industry events, the VISION G3 will be available for viewing at Infinity’s facilities in Green Bay Wisconsin and Bologna Italy during their open house showcase, and anytime online at infinitymec.com/vision-g3-wrapper.

LSS gibt Ihnen die vollständige Kontrolle

On a production line, every second counts. Any disturbance, like a bottleneck or a jam can cause a reduction in Overall Equipment Effectiveness, resulting in lost time, and lost revenue.

It may sound cliché, but in production lines, time is money, and it was for this reason Infinity developed Line Synchronization and Simulation software.

Infinity’s LSS, gives operators the ability to control the speed of the line and harmonize the downstream system as a single unit.

LSS is able to accomplish this by monitoring downstream machine process data, the accumulator level and the line’s target speed. LSS sets the target speed for the line, based on individual bottlenecks, and then controls speeds for all the equipment.

This is essential in tissue converting lines as they need the ability to feed enough product for wrappers to continuously run, while the downstream equipment needs to be able to run faster than target speed when there is a backlog.

The LSS software continuously monitors downstream machine process data including the machine speed and material status. Then LSS adjusts the line to compensate for any changes that arise. These adjustments could be anything from increasing the speed of a leg, to letting an accumulator fill to a certain level or even slowing down the line to clear a disturbance.

The data used by LSS is controlled by the master programmable logic controller which can be shared with another machine PLC or a dedicated PLC.

Identifying bottlenecks, and altering line speed in accordance with upsets ensures that machines are operating at their maximum uptime and least mechanical stress. By reacting to line irregularities, LSS can resume full production quickly, resulting in increased OEE.

However, Infinity LSS doesn’t just react to changing circumstances, it also anticipates them. LSS can account for changes in raw materials on a machine, the speed of the machine can be increased to create a time buffer for the change in material.

In addition to this, LSS can also anticipate disruptions by monitoring for a presence or absence of products in a certain area. If there is an irregularity in the flow of a product, we can pause the line for a conveyor jam.

Since different products and different configurations can change the target speed, requirements, or overall objectives of a line, LSS is completely customized based on a consumer’s unique requirements. Features like output path adjustments, accumulator level monitoring and log distribution can all be tailored for a consumer.

Another key component of Infinity’s LSS is the simulation service. By using Emulate 3D software, Infinity emulation engineers can create a functional three-dimensional virtual version of the product line. This allows customers to see their line in action, test different product formats, check photo-eye positions, speeds and production data, all before installation.

In essence, our LSS program allows our customers to have confidence in their purchase by giving them a virtual check-out.

The LSS service also offers customized Human Machine Interfaces that display the entire packaging system. The LSS HMI gives the operator a visual of the states/faults of the conveyor section, and also allows them to change drive section controls from automatic to local.

From the top down, Infinity LSS was designed with efficiency in mind. This unique service allows for maximum OEE, pre installation testing and personalized, user-friendly HMI. To learn more about our LSS services, reach out to your nearest Infinity Sales office.