Spanish tissue paper company, Manipulados Lisma, invests in Infinity Machinery

Growing Spanish tissue manufacturer, Manipulados Lisma, recently purchased three machines from Infinity Italia for its facility in Toledo, Spain.

The purchase breaks new ground for Infinity, as Lisma’s order includes the first VISION G3 multipack wrapper to be installed in the European Union, and the first Infinity Infusion modular system with an i18 bundler and C15 casepacker to be installed in the EU.

Infinity has long been a global leader in automated tissue paper packaging, and Lisma’s investment expands Infinity’s already growing influence in the European market.

Infinity prides itself on manufacturing machinery that is operator-friendly and capable of quick changeovers, two factors that are key to Lisma’s production line. The Infinity machines also have some of the smallest footprints on the market, allowing Lisma to more efficiently utilize space in their facility.

The VISION G3 multipack wrapper is the newest machine release from Infinity, and it features a multitude of new innovations. The machine can produce poly wrapped, paper wrapper, paper tucked, and facial tissue packs, giving Lisma ultimate versatility in production formats. The VISION G3 also features a unique telescoping poly unwind (patent pending), which allows for faster production and better pack quality.

Lisma selected an Infinity i18 Bundler for their line because it is capable of producing large, “European” style bundles for B2B commerce. The i18 will also enable Lisma to run a diverse range of products, as the bundler can run tissue rolls, tissue packs, individual bathroom towels, individual household towels, boxed products, diapers, and industrial rolls.

Infinity’s C15 casepacker has long been a fixture of the tissue products packaging industry, boasting low maintenance and high performance all within a small footprint. Lisma will be able to complete product changeovers on the C15 in as little as 20 minutes, ensuring that they will have maximum overall equipment effectiveness.

While the i18 and C15 are impressive machines in their own right, their compatibility with Infinity’s Infusion Modular system put them in a class above the rest. Developed by Infinity engineers to increase efficiency in a reduced footprint to that of similar linear machines, the 3 in 1 Infusion Modular system incorporates fixed docking stations to create increased packaging flexibility. Bundler, casepacker, and even bagger modules can be attached and detached from a common infeed module, allowing for three different machine combinations in one.

For more than 35 years, Lisma has been a family-owned and operated company, committed to continuous improvement. Lisma has risen to prominence in the European Tissue industry, as it successfully opened in new international markets. Lisma’s purchase of Infinity machinery ensures that they will have the equipment to continue their expansion for many years to come.

WEPA Invests in Infinity Equipment for Multiple Locations

WEPA, a leading tissue product manufacturer in Europe, recently purchased seven machines from Infinity Italia for their facilities in Troyes, France, Swalmen, Netherlands and Piechowice, Poland.

Infinity is supplying two Eclipse T4 Wrappers and two i18 Bundlers for WEPA’s Troyes facility, one Eclipse T4 Wrapper, and one i18 Bundler for WEPA’s facility in Swalmen and in Piechowice, WEPA selected an Infinity C-15 Casepacker for their folded products division.

WEPA was drawn to Infinity’s equipment due to its unique combination of American ruggedness and Italian design refinement. The i18 Bundler is a perfect fit for WEPA’s facilities as it was designed specifically with European markets in mind. The poly bundler features an integrated diverter and flight bar system for easy product collation, as well as an automatic poly reel splice and poly pull-out cart for safe and quick poly loading. In addition to this, an active vacuum comes standard on the i18 Bundler. Excess air is sucked from the bundles’ pre-discharge resulting in a tight, crisp poly wrap.

Another advantage of the i18 Bundler is its compatibility with Infinity’s Infusion modular system. By utilizing the fixed infeed section, the i18 can be coupled with modules, such as an Infinity Casepacker or Bagger. The modules are moved in and out of the docking station which gives WEPA ultimate secondary packaging flexibility without taking up any additional floor space. The “industry original” Infusion modular system was designed by Infinity engineers to overcome the limitations of fixed linear machines while reducing capital investment. As trends in packaging are continuously evolving, Infinity’s innovation allows WEPA to quickly adapt to market changes.

As for primary packaging, WEPA ordered Infinity’s Eclipse T4, which is known as one of the most durable wrappers on the market. Infinity’s commitment to efficiency is on full display in the Eclipse’s overhead system. The Eclipse T4 utilizes a durable AT20 belt and only 24 trolley sections, this decreases the changeover time between different package configurations. Additionally, Infinity’s Eclipse T4 is designed to accept four lanes of infeed and can run an optional fifth. The infeed lanes also have wide diameter capabilities, ensuring the Eclipse will keep pace with new product developments in the Troyes and Swalmen facilities.

Infinity’s reach in Europe was further increased by WEPA’s purchase of the C15 Casepacker for their Piechowice facility. Infinity’s C15 boasts an extremely straightforward design which allows for a 20-minute changeover between case sizes and configurations. Although the machine’s design is simple, its build is robust as the frame and guarding are both constructed using steel. The C15 is also capable of speeds up to 300ppm per index arm, providing maximum efficiency at the infeed of the machine.

A defining feature of the C15 is the machine’s fully positive case erection. Vacuums are utilized on both sides of the case providing a consistent case opening. The positive case erection is perfect for large and small cases, cases with bad score marks as well as cases that are glued together. This design feature will allow WEPA to run at optimal efficiency.

Echoing WEPA’s industry 4.0 efforts, the transaction with Infinity didn’t end with the machine purchase. Emulation engineers from Infinity offices traveled to Swalmen and will be traveling to Troyes to provide Virtual reality training to WEPA employees. This included a fully interactive VR machine changeover, which allowed WEPA employees to become familiar with their machines weeks before they arrived at their facilities.

Infinity also equipped the machines with a data collecting and remotely accessible eWON device. This enables WEPA to track production times, faults, and speed. This information will be accessible remotely through email notifications or web browsers. The Troyes facility will also have light annunciation on their i18 Bundlers to provide changeover assistance. The light annunciation illuminates change-over points on the adjustment scales.

WEPA’s recent investment reflects Infinity’s growing reach in the European market and is further proof Infinity is the global leader in automated tissue paper packaging machinery.

Ahora de vuelta en el escenario mundial

Infinity Machine and Engineering Corporation, líder mundial en equipos automatizados de envasado de pañuelos, se complace en presentarse una vez más en el escenario mundial.

Infinity Machine and Engineering Corporation, líder mundial en equipos automatizados de envasado de pañuelos, se complace en presentarse una vez más en el escenario mundial.

Debido a la pandemia de coronavirus, muchas ferias comerciales y eventos de la industria se suspendieron. Sin embargo, a medida que el mundo pasa a la siguiente etapa de gestión de la pandemia, muchos eventos de la industria vuelven a estar programados.

Infinity aparecerá en Mundo de tejidos Miami del 16 al 18 de marzo, Papel tisú y papel Bangkok del 14 al 16 de septiembre, y finalizarán su gira mundial en Lucca, Italia, en el MIAC del 12 al 14 de octubre. Infinity se presentará en el stand B30 en Tissue World Miami, el stand D10 en Tissue and Paper Bangkok y el stand 27M en MIAC.

Si bien el mundo parecía estar en pausa durante los últimos meses, los ingenieros de Infinity trabajaron arduamente para desarrollar las últimas innovaciones en el empaque automatizado de productos de papel sanitario. El pináculo de estas actividades y el enfoque clave de la gira mundial 2022 de Infinity es su nuevo envoltorio multipack VISION G3.

Capaz de producir paquetes de cinco carriles de ancho, tres capas de altura y seis filas de profundidad, la VISION G3 redefine la versatilidad de las envolvedoras de paquetes múltiples. La VISION G3 también puede producir paquetes envueltos en polietileno, paquetes envueltos en papel, paquetes envueltos en papel y paquetes de pañuelos faciales.

Los ingenieros de Infinity tampoco sacrificaron la velocidad por esta mayor versatilidad. Debido a un revolucionario diseño telescópico (pendiente de patente) en el desenrollado de polietileno, la VISION G3 es capaz de alcanzar velocidades más rápidas y mejorar la calidad del paquete.

Tissue World Miami, Tissue and Paper Bangkok y MIAC son las oportunidades perfectas para aprender más sobre VISION G3 de primera mano del experimentado personal de ventas de Infinity. Sin embargo, si no puede asistir a estos eventos de la industria, el VISION G3 estará disponible para su visualización en las instalaciones de Infinity en Green Bay, Wisconsin y Bolonia, Italia durante su exhibición de puertas abiertas, y en cualquier momento en línea en infinitymec.com/vision-g3-wrapper.

LSS le da control total

On a production line, every second counts. Any disturbance, like a bottleneck or a jam can cause a reduction in Overall Equipment Effectiveness, resulting in lost time, and lost revenue.

It may sound cliché, but in production lines, time is money, and it was for this reason Infinity developed Line Synchronization and Simulation software.

Infinity’s LSS, gives operators the ability to control the speed of the line and harmonize the downstream system as a single unit.

LSS is able to accomplish this by monitoring downstream machine process data, the accumulator level and the line’s target speed. LSS sets the target speed for the line, based on individual bottlenecks, and then controls speeds for all the equipment.

This is essential in tissue converting lines as they need the ability to feed enough product for wrappers to continuously run, while the downstream equipment needs to be able to run faster than target speed when there is a backlog.

The LSS software continuously monitors downstream machine process data including the machine speed and material status. Then LSS adjusts the line to compensate for any changes that arise. These adjustments could be anything from increasing the speed of a leg, to letting an accumulator fill to a certain level or even slowing down the line to clear a disturbance.

The data used by LSS is controlled by the master programmable logic controller which can be shared with another machine PLC or a dedicated PLC.

Identifying bottlenecks, and altering line speed in accordance with upsets ensures that machines are operating at their maximum uptime and least mechanical stress. By reacting to line irregularities, LSS can resume full production quickly, resulting in increased OEE.

However, Infinity LSS doesn’t just react to changing circumstances, it also anticipates them. LSS can account for changes in raw materials on a machine, the speed of the machine can be increased to create a time buffer for the change in material.

In addition to this, LSS can also anticipate disruptions by monitoring for a presence or absence of products in a certain area. If there is an irregularity in the flow of a product, we can pause the line for a conveyor jam.

Since different products and different configurations can change the target speed, requirements, or overall objectives of a line, LSS is completely customized based on a consumer’s unique requirements. Features like output path adjustments, accumulator level monitoring and log distribution can all be tailored for a consumer.

Another key component of Infinity’s LSS is the simulation service. By using Emulate 3D software, Infinity emulation engineers can create a functional three-dimensional virtual version of the product line. This allows customers to see their line in action, test different product formats, check photo-eye positions, speeds and production data, all before installation.

In essence, our LSS program allows our customers to have confidence in their purchase by giving them a virtual check-out.

The LSS service also offers customized Human Machine Interfaces that display the entire packaging system. The LSS HMI gives the operator a visual of the states/faults of the conveyor section, and also allows them to change drive section controls from automatic to local.

From the top down, Infinity LSS was designed with efficiency in mind. This unique service allows for maximum OEE, pre installation testing and personalized, user-friendly HMI. To learn more about our LSS services, reach out to your nearest Infinity Sales office.

Monalisa invierte en línea de envasado completa de Infinity.

Infinity Machine and Engineering Corp., a world-wide leader in packaging machinery for the tissue industry, will supply Monalisa, located in Nonsan-si, South Korea, a full packaging line. The line will be installed by June of 2021.

Infinity is supplying all the equipment on the packaging line between the log saw and the palletizer. The packaging line includes one (1) Eclipse T4 wrapper, one (1) EPXL bundler, one (1) ItaPack handle applicator (integrated by Infinity) and the conveyor system. Monalisa chose Infinity for this project because they required a system that was flexible for their changing market and they desired robust equipment that will last the next 20+ years. All equipment being provided is built with Infinity’s notable machinery characteristics like rugged steel frames, oversized bearings and overall top-of-the-line componentry. In addition, all machinery uses a SIEMENS processor.

The Eclipse T4 wrapper on this line will be able to run everything from single roll bath tissue to larger bath tissue pack options like 30-packs and 48-packs. The Eclipse T4 wrapper has become a tissue industry staple during the last four years with over 100 wrappers now in production throughout the world.

Not only will the Eclipse T4 wrapper provide more packaging options but so will the bundler on this line. The bundler is called the EPXL. It has a wide product range and can make small and large bundles. The EPXL bundler has a continuous motion design with linear servo movement of the knife and seal jaw. This allows Monalisa to fulfill their current bundle demands, but also gives them the ability to make bundles

with graphics applied to the poly. Since this bundler is continuous motion, it is able accurately follow registration marks and auto correct for misalignment. Other features of the bundler include an integrated diverter and flight bar system for easy product collation, automatic poly reel splice and poly pull out cart for safe poly loading.

Finally, the conveyor system on Monalisa’s line plays an important role in the creation of the product. The system is equipped with an Itapack Handle applicator and every turning, tipping and knock-down device. This allows Monalisa to apply handles to the packs in any orientation and position the packs into the bundle in any orientation as well.

Infinity’s line that has been delivered to Monalisa was designed, built and tested with extensive customer input throughout the COVID-19 pandemic. Monalisa was able to see weekly progress through Teams meetings and check the line out virtually. This project truly represents what Infinity stands for robust, flexible, custom and customer-focused tissue packaging solutions. The line will allow Monalisa to offer new packaging options to their customers and will give Monalisa the ability to do this for years to come.

Infinity Machine & Engineering Corp. expande sus instalaciones de ingeniería y fabricación

Debido al tremendo crecimiento, Infinity Machine & Engineering Corporation, un fabricante líder en el mercado de equipos de empaque de papel tisú que incluye envoltorios, empaquetadores, empaquetadores de cajas, desviadores, transportadores y selladores de cajas, ha iniciado una nueva expansión de 8,900 metros cuadrados (96,000 pies cuadrados). Actualmente, Infinity se divide en cuatro instalaciones, tres de las cuales están en Green Bay, WI USA y la cuarta en Bolonia, Italia.

La nueva instalación ampliada en Green Bay, EE. UU. Tendrá un total de 16.000 metros cuadrados (172.000 pies cuadrados), que junto con sus instalaciones en Bolonia, Italia de 1200 metros cuadrados (13.000 pies cuadrados), posicionarán perfectamente a Infinity para continuar hacer crecer su negocio y servir a los clientes de Infinity en todo el mundo.

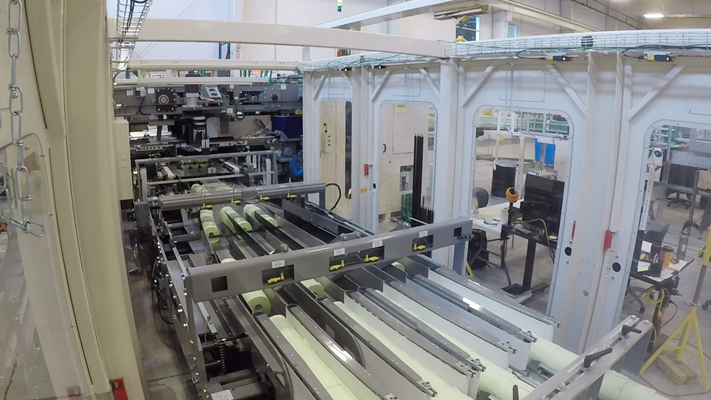

El propósito de la nueva expansión es permitirle a Infinity ofrecer una mayor capacidad de fabricación a los clientes, implementar mejoras en el proceso de fabricación, expandir las ofertas de la línea de productos, tener un área dedicada a I + D, expandir sus instalaciones de capacitación y permitir configuraciones completas de líneas de empaque.

Algunas características nuevas de la expansión del edificio incluyen; un sistema de carro monorraíl para piezas con recubrimiento en polvo que duplicará con creces la capacidad de pintura, agregando seis bahías de ensamblaje final adicionales (actualmente hay 13) y también agregando áreas adicionales de “preconstrucción” para acelerar la producción. La nueva expansión también ofrecerá un taller de maquinaria ampliado, un laboratorio de control de calidad de última generación para verificar la precisión de las piezas y 1.200 metros cuadrados adicionales específicamente para la producción de transportadores. La instalación de fabricación ampliada está diseñada con la intención de crear un flujo eficiente de fabricación de piezas, pintura, preparación de trabajos, ensamblaje, caja y envío de la máquina. La luz natural en toda la tienda también crea un ambiente luminoso y abierto.

Además, Infinity también está ampliando sus oficinas de ingeniería para permitir una mayor capacidad de ingeniería. La nueva oficina permitirá a Infinity tener una plantilla total de ingenieros de casi 40 ingenieros. Actualmente, Infinity emplea a unos 30 ingenieros. Infinity también tendrá un espacio dedicado a la sincronización y simulación de la línea de envasado, que contará con un estudio de realidad virtual y grandes monitores para las inspecciones de línea simuladas antes de la instalación real. Además, el área de servicio al cliente se ampliará para permitir más instalaciones de resolución de problemas remotas, monitoreo de máquinas, colaboración de ingeniería y mayor capacidad.

Entre los años 2016 y 2019, Infinity ha duplicado su tamaño en términos de envíos e ingresos de máquinas. El crecimiento de Infinity, sin embargo, no está mejor representado por la cantidad en ventas o el número de máquinas en el mercado, sino por las personas que componen la empresa y su valiosa base de clientes. En 2016, Infinity tenía 85 empleados y solo cuatro años después, Infinity ahora emplea a más de 170 personas entre ingeniería, compras, producción, envío y servicio. La expansión del edificio seguirá este crecimiento y permitirá que Infinity sirva aún más al mercado mundial con equipos de envasado de tejidos robustos, fiables y tecnológicamente avanzados.

Ladrillo a ladrillo, proyecto a proyecto, idea a idea, la intención de Infinity es crecer sin límites y hacer nuestro mejor esfuerzo para ayudar a nuestros clientes a alcanzar su máximo potencial. En prácticamente todas las facetas de la organización Infinity, Infinity se esfuerza por alcanzar la perfección y proporcionar longevidad y continuidad para nuestros clientes, nuestros empleados y nuestra comunidad. Administramos nuestras operaciones mientras nos enfocamos en tres principios importantes: siempre damos nuestro mejor esfuerzo, trabajamos en armonía con nuestros valores y simplemente hacemos lo que decimos que haremos.